Pressure-sensitive adhesives (PSAs) are commonly employed in packaging to assemble or support the design of a finished product. It is one of the most efficient and effective methods for bonding, compared to welding or nailing. In industries related to packaging, such as crate manufacturing, these adhesives provide reliable and secure bonding solutions.

How We Can Help

Because PSAs can bond numerous materials like plastic, paper, metal, glass, wood, it’s a great go-to adhesive solution for general-purpose assembly. There are various advantages of using ASA-3942 in crate manufacturing:

- Being able to bond to a variety of substrates makes ASA-3942 an ideal choice to accommodate different packaging materials and protected item in the crating business

- ASA-3942 has high initial tack and excellent cohesion which means it’s super tacky and will tightly bond the substrates in place.

- High softening point of 239 oF allows the substrates to stay securely bonded in non-climate-controlled environments such as trucks and storage areas in the hot weather.

- ASA-3942 is a permanent pressure sensitive with added rosin tackifier which gives it the tacky super power to ensure the bonding remains intact.

- It remains permanently tacky allowing operators workable time to position the foam or other substrates in the crate.

Due to long and extended open time, hot melt PSAs are ideal for precoating, or situations that require the adhesive to remain sticky after the application such as in product assembly in crate manufacturing. Ultimately, they save time in production compared to liquid adhesives as they require no setup or long curing time.

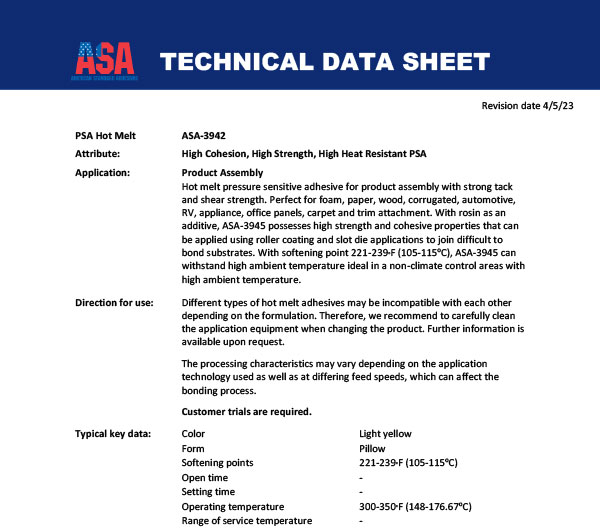

About ASA-3942

American Standard Adhesive’s ASA-3942 is formulated for difficult-to-bond surfaces and substrates. The formulation is suitable for various surfaces including metal, plastic, wood, and glass. ASA-3942 possesses high strength and cohesive properties that can be applied using roller coating and slot die applications to join difficult-to-bond substrates. With a softening point of 221-239oF, ASA-3942 can withstand high ambient temperatures.

ASA-3942 Applications

- Automotive

- RV

- Appliance

- Office panels

- Carpet and trim attachment

- Packaging

- General product assembly

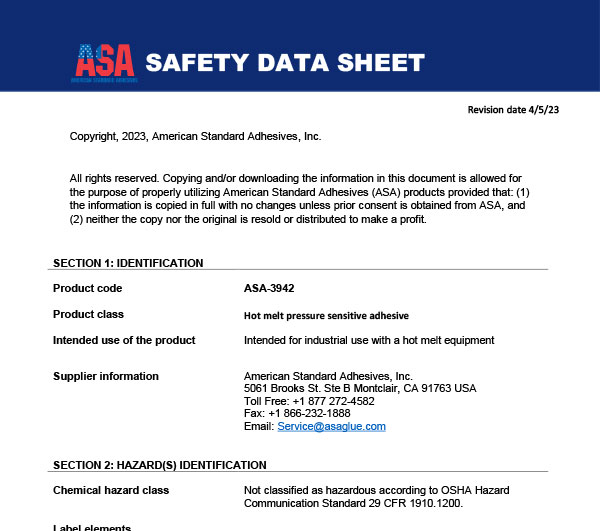

About Us

American Standard Adhesives (ASA) offers a wide range of hot melt technology solutions to support the manufacturing industries in North America. Variables such as substrates, operating conditions, temperature, and equipment affect the choice of hot melt. Feel free to contact us for more information about our products.