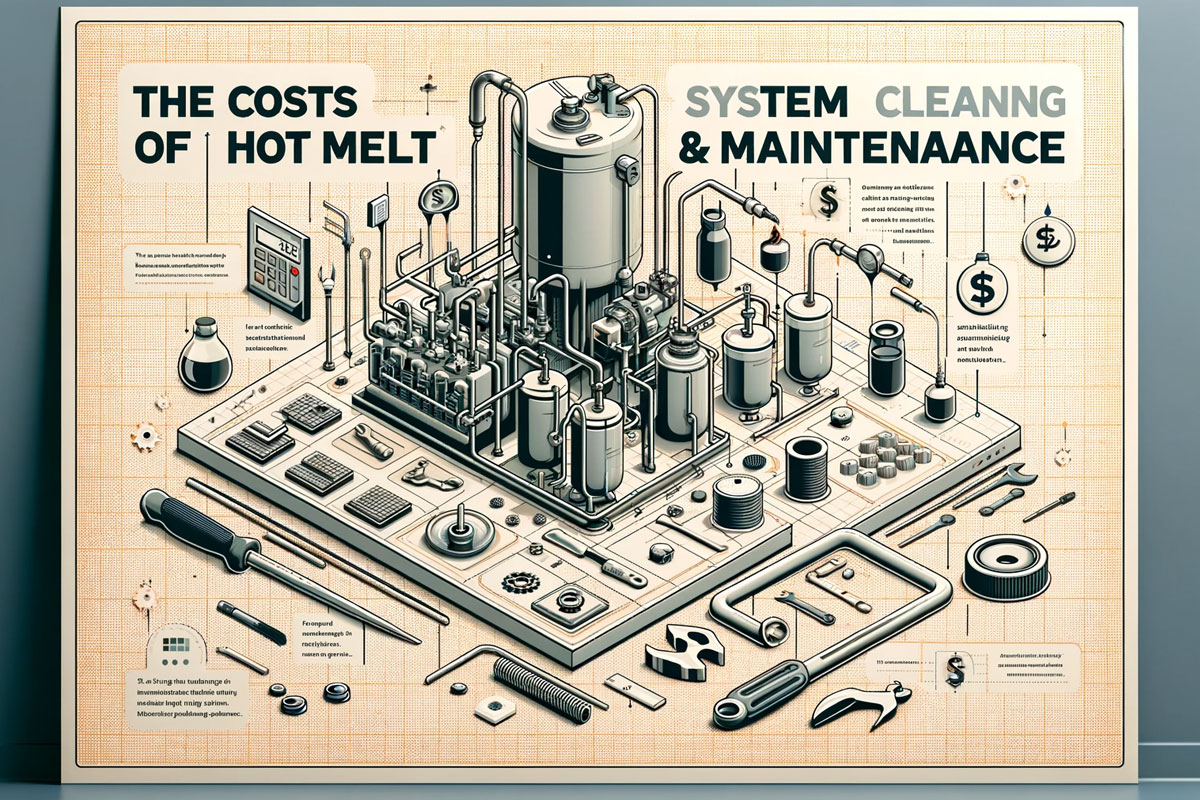

Take a Strategic Approach to Hot Melt System Maintenance to Minimize Costs and Downtime

While business often think of how to optimize their adhesive performance, when it comes to end-of-line packaging applications, the battle against adhesive char in hot melt glue systems is an ongoing challenge that is frequently neglected. For many businesses relying on tank-based melting processes, the focus shifts towards maintaining production efficiency. However, neglecting the upkeep of these systems can lead to costly consequences such as downtime and a rush for replacement parts. Here are some suggestions from the team at ASA Glue that can help minimize both costs and downtime.

Addressing issues reactively often results in a frantic race against time, with maintenance managers scrambling to acquire urgently needed replacement parts. In extreme cases, equipment experts might be flown in overnight to revive halted packaging lines. A simple purge and filter replacement may fall short for systems that have been neglected for too long. It’s not uncommon for a hot melt glue system to necessitate complete disassembly, with parts either replaced or treated in hot oil to eradicate char from inaccessible corners. Following this, the system is reassembled, incorporating new seals and undergoing recalibration.

The key to mitigating these challenges lies in establishing a proactive maintenance process. ASA Glue, with its commitment to adhesive excellence, recommends that businesses deploy dedicated personnel for regular cleaning and purging hot melt systems on a predetermined schedule.

Proactive Measures for Maximum Uptime

While proactive maintenance proves beneficial in preventing catastrophic failures, it is not without its costs.

Each system purge incurs expenses in several areas:

* Wasted Adhesive: Purging a more extensive tank-based system may result in losing up to 10 lbs. of ASA Glue adhesive.

* Cleaners: Various substances like paraffin wax and equipment manufacturer recommended cleaners are used to eliminate char adhered to melters, hoses, and applicators.

* Downtime: Multiple cleaning cycles with different cleaners might be necessary, leading to extended system downtime.

* Replacement Parts: New filters, nozzles, and seals are essential components contributing to the overall cost.

* Labor: Whether it’s an in-house team or a specialized third-party resource, personnel dedicated to system cleaning incur labor costs.

Despite these expenses, the proactive approach is a strategic investment, considerably more cost-effective than dealing with a reactive maintenance event. On average, a thorough purge of a tank-based hot melt glue system, including tank, hoses, applicators, and replacing filters, seals, and nozzles, takes 4-6 hours.

Staying Ahead Through Information and Collaboration

To stay ahead in the realm of hot melt equipment maintenance, staying informed about available options and best practices is crucial. Apart from consulting equipment manufacturers and industry publications, maintaining connections within the organization can yield valuable insights into process improvements and new equipment options.

In many cases, different facilities within the same company may employ diverse equipment for identical packaging applications. Despite being nearby, information sharing among plant managers might not always reach the engineering or maintenance personnel at the ground level. Bridging these communication gaps is vital to preventing maintenance issues that can escalate costs and hinder productivity.

By embracing a proactive stance, businesses can navigate the complexities of hot melt system maintenance, ensuring a seamless and cost-efficient production process. Choosing a hot-melt option with a better ROI is another option that can be considered.

Here at ASA Glue, we are always ready to help. Don’t hesitate to contact us for more information.