The Use of Hot Melt in the Berry Packing Industry

Hot melt glue is essential for the agriculture industry’s end-of-line packaging and product assembly. Although adhesives represent a tiny portion of the global food packaging industry, they are crucial in enhancing packaged food’s sustainability and effectiveness.

Food and consumer safety are critical for handling food-related products, packaging, and adhesive applications. Packaging is vital for berries to maintain their quality and shelf-life until reaching the consumer. Berry packers use clamshells, which do not require adhesives due to their self-locking mechanism, and food-grade absorbent papers that require sealants to keep them in place to secure the produce during transit and to increase shelf life.

The hot melt gluing clamshell to absorbent paper creates a temporary bond that allows the substrates to secure in place but can still be peeled off without a fiber tear. This temporary bond, where the hot melt forever remains tacky, is one of the characteristics of pressure-sensitive glue.

Clamshell to Paper

Safe food packaging is critical in today’s industry as fresh fruits and crops travel long distances in the global supply chain. The absorbent paper extends the shelf life of fresh berries by absorbing moisture and slowing down decay over a while.

Adhesives are an essential component to secure the two substrates and minimize movement. There are two main types of hot melt applications to meet the needs of the berry packing industry: the pressure-sensitive glue for product assembly application and the EVA hot melt for end-of-line carton sealing application.

How Can American Standard Adhesives Help?

American Standard Adhesives has partnered with berry packers in North America to provide adhesive solutions for their automated operations. They are often used for corrugated materials, papers, and PET plastics.

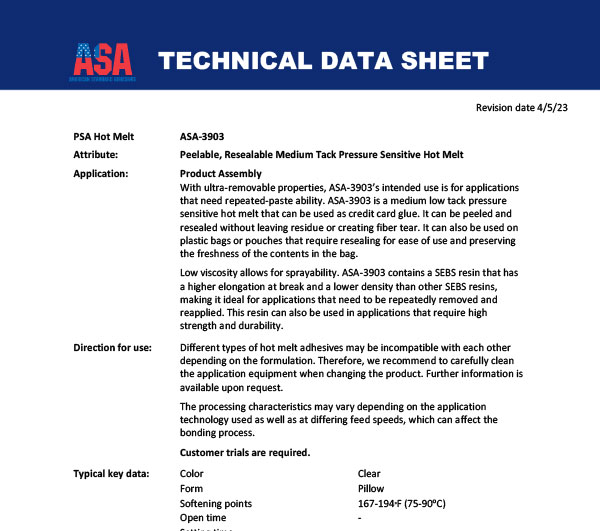

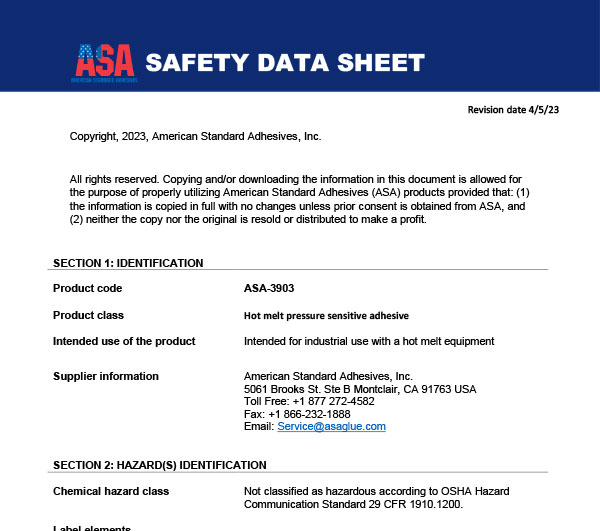

We recommend using ASA-3903 for clamshell to paper. It is a pressure-sensitive hot melt (PSA) that always remains tacky and can be peeled off the substrates without any residue. The tack strength is medium-low, which means the adhesive is strong enough to secure the bond without damaging it to fiber tears.

For the corrugated box forming and closing, there are several options. We recommend our hybrid metallocene adhesive ASA-3246ML for its performance in high heat resistance, pot stability, and fiber penetration in corrugated-to-corrugated bonding. Moreover, its fast setup time allows for short compression in an automated line.

Food safety is the foremost and vital requirement for transportation, storage, and food packaging. That’s why most of our adhesive solutions meet the Food and Drug Administration (FDA) 175.105 guidelines for food packaging adhesives.

About Us

American Standard Adhesives (ASA) offers a wide range of end-of-line packaging adhesives to support the various requirements of our customers. Essential considerations such as substrates, operating conditions, temperature, and equipment affect the choice of hot melt.

Don’t hesitate to get in touch with us if you need more clarification about selecting a suitable adhesive for your application and to inquire more about how we can help your next project.